WELDING & BRAZING

- Home >

- Capabilities & Services >

- Welding & Brazing

Understanding Welding & Brazing

Since the dawn of time humans have made tools, using a wide variety of stone, wood, fiber, metal and other materials. As tools became more specialized, people found ways to combine the materials into increasingly complex devices.

Joining pieces of metal, including different types of metals, permits designers to create the enormously complicated machines that power our modern civilization.

Useful for a huge range of applications across many industries, welding and brazing are two methods for joining pieces of metal together, but with important differences.

Welding

Welding is a process where two or more parts are joined together by melting them at the contact point and allowing them to cool and fuse. The term applies equally to both metal and thermoplastic parts.

The result is a permanent bond that can be stronger than the original materials. Welding typically employs high heat to melt the parts, though intense pressure or a combination of the two. Welding often includes a filler material similar to the base material to fill in gaps and enhance the strength of the weld.

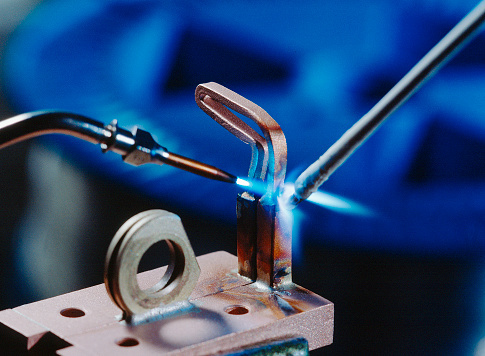

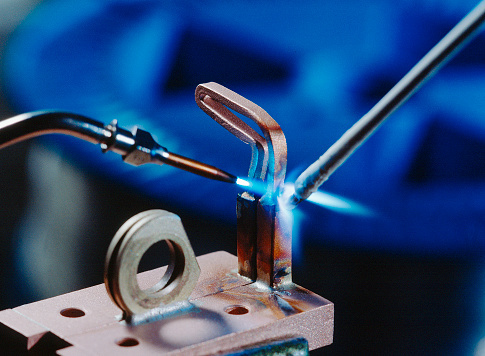

Brazing

Brazing involves joining pieces of metal using a filler metal to create a strong bond between two close-fitting parts. The filler material has a lower melting point than the metal work pieces being joined.

Where welding melts the work pieces, brazing heats only enough to melt the filler so it will wick or flow via capillary action into the joint between the two parts. This results in less distortion of the base metal parts and allows joining of two dissimilar base metals with different melting points, something welding frequently cannot accomplish.

Side Note: Soldering, which is similar to brazing, uses filler materials that melt at a lower temperature, typically below 450°C.

Choosing the Right Joining Service

Welding is the right choice if high strength is critical to your application.

Consider requesting our brazing service if you need to join two dissimilar metals and need to minimize potential heat distortion on the work pieces.

If you're not sure which option will be optimal for your project, reach out and we'll be happy to talk it though with you.

EMI's Welding & Brazing Services

EMI's joining services include:

- MIG Welding -- also known as Gas Metal Arc Welding (GMAW)

- TIG Welding -- also known as Gas Tungsten Arc Welding (GTAW)

- Purge Welding -- especially for reactive metals like stainless steel and titanium

- Low Temp Welding

- Fuse Welding

- Torch Brazing

- Soldering

Given EMI's long history of serving the Food Processing & Packaging industry it's no surprise we are well-versed in completing projects that require compliance with USDA 3-A sanitary welding standards to produce joints that are strong, leak-free, and easy to clean.

Welding & Brazing Applications

- Marine and & Oceanographic Buoys and Frames

- Material Handlers

- Dumpers

- Loaders

- Conveyors

- Fillers

- Feeders

- Mixers

- Blenders

- Deboners

- Labelers

- Carts

- Cages

- Enclosures

Welding & Brazing Materials

- Iron

- Stainless Steel

- Carbon Steel

- Aluminum

- Titanium

Got an Urgent Job?

Testimonials

%20-%20DTM%20Packaging%205%20Light%20Blue.png)

%20-%20Ocean%20Imaging%202%20Light%20Red.png)

%20-%20Polymer%20Corp%203%20Light%20Green.png)

Why EMI?

Choosing the right outsourcing partner for your precision manufacturing needs can be the difference between success or failure for a given project. The question is how to choose.

The answer is to optimize for the right relationship. Choose a partner that supports your supply chain needs by delivering responsive service, open two-way communications, and on-time delivery.

For more than a half-century and continuing to this day, EMI always seeks to co-create the right relationship by prioritizing our partners' success.

Our Promise:

“More than Parts: Partnership.”

Contact us today to start building the right relationship.

%20Transparent%20Cropped.png?width=218&height=84&name=EMI%20Logo%20PNG%20(360%20x%20144%2072%20DPI)%20Transparent%20Cropped.png)