QUALITY ASSURANCE

Every Part, Every Assembly, Every time

- Home >

- Capabilities & Services >

- Quality Assurance

Committed to Quality At Every Step, From Start to Finish

The old saying is true - what you get out is what you put in. At EMI, our objective is to deliver quality outcomes for our customer partners, so everything we put in must match that quality goal.

In support of that mission, EMI is ISO 9001:2015 certified, which is only right for a company that promises "More than Parts: Partnership."

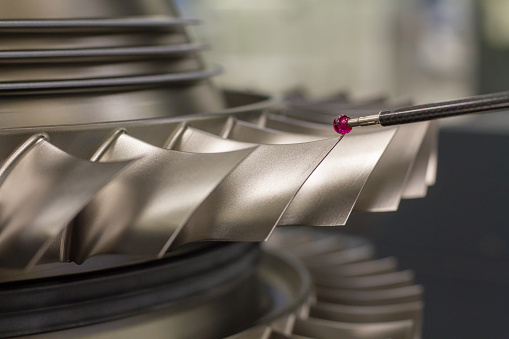

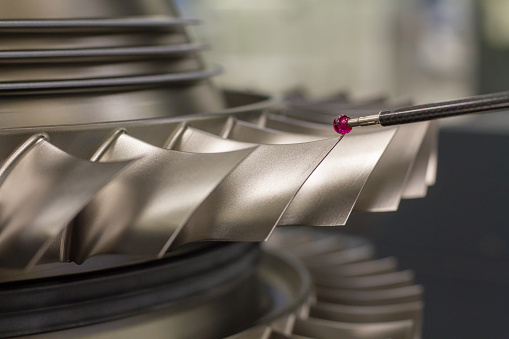

In addition to a wide range of annually calibrated CMMs (Coordinate Measuring Machines) and other machines and gauges to verify the quality of production, we also invest in key digital technologies to capture and retain measurement data so we can issue certify the results for our customer partners.

Click here to view EMI's Manufacturing Equipment & Facilities list or download a printable copy.

EMI's Quality Services

Before we perform any work, EMI confirms the AQL (Acceptable Quality Limit) and any CTQ (Critical to Quality) parameters as set by the customer.

During production, EMI follows a strict FAI (First Article Inspection) protocol for each step of the process, with additional inspections as dictated by each customer's quality goals.

For acceptance sampling for larger volume work we can follow the ANSI/ASQ Z1.4 or work to a custom standard as needed by our customer partners.

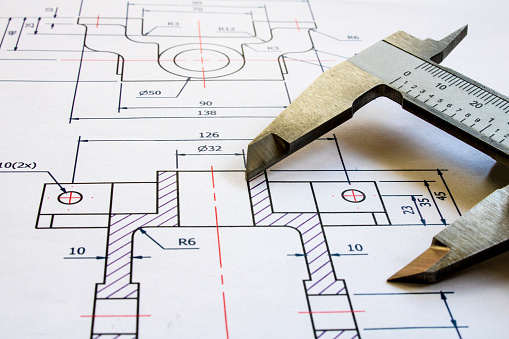

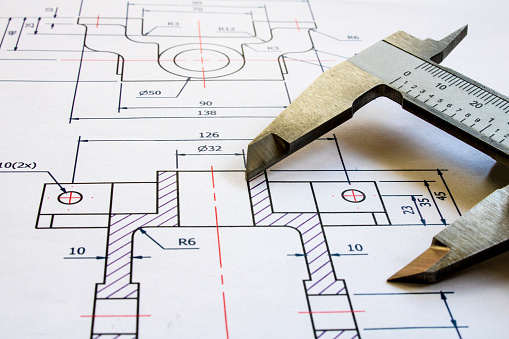

As part of our ISO 9001:2015 quality management system, we use SolidWorks and other software to verify dimensional conformance to our customers' CAD drawings.

We also manage inspection reporting and data retention via the IDEAGEN InspectionXpert software platform.

We are happy to provide certificates for our customers that require them as part of our overall service.

Finally, to ensure a great finished product, our quality assurance equipment is calibrated annually.

Of course, we are always happy to show off our Quality Assurance department to new and existing customer partners. Reach out to schedule a tour as part of preparing for your next project.

EMI's Quality Assurance Equipment

- CMM -- Carl Zeiss Spectrum with RDS (2)

- CMM -- Brown & Sharpe Microval

- XRF -- Hitachi X-MET8000 Optimum Handheld Analyzer

- CMM VISION SYSTEM -- Keyence IM8030

- COMPARATOR -- Mitutoyo with Quadracheck

- TOOLMAKER'S MICROSCOPE -- Mitutoyo Toolmaker's Microscope

- HEIGHT TESA -- Micro-Hite (4) ... 16-24"

- HEIGHT -- Height Gauges

- HARDNESS -- Hardness Tester

- VERNIER CALIPERS ... full sets (from 4" to 6 feet)

- MICROMETERS ... full sets

- GAUGE BLOCKS ... full sets

- PINS ... full sets

- BORE GAUGES -- Dial Bore Gauges to 16"

- BORE GAUGES -- Sunnen Bore Gauges ... full sets

- THREAD GAUGES ... full set

- PLUG GAUGES ... full set

- RING GAUGES ... full set

- SURFACE ROUGHNESS -- Mitutoyo Surface Roughness Gauge

- GRANITE SURFACE PLATES ... from 18" square to 3' x 5'

Click here to see EMI's Production Equipment & Facilities page.

For easy reference, print or download a copy of our Capabilities Card & Facilities List.

Got an Urgent Job?

Testimonials

%20-%20Paquette%20%26%20Assocs%201%20Light%20Green.png)

%20-%20Ocean%20Imaging%204%20Light%20Gray.png)

%20-%20DTM%20Packaging%204%20Light%20Blue.png)

Why EMI?

Choosing the right outsourcing partner for your precision manufacturing needs can be the difference between success or failure for a given project. The question is how to choose.

The answer is to optimize for the right relationship. Choose a partner that supports your supply chain needs by delivering responsive service, open two-way communications, and on-time delivery.

For more than a half-century and continuing to this day, EMI always seeks to co-create the right relationship by prioritizing our partners' success.

Our Promise:

“More than Parts: Partnership.”

Contact us today to start building the right relationship.

%20Transparent%20Cropped.png?width=218&height=84&name=EMI%20Logo%20PNG%20(360%20x%20144%2072%20DPI)%20Transparent%20Cropped.png)