ASSEMBLY SERVICES

Streamlining Your Supply Chain

- Home >

- Capabilities & Services >

- Value Added Services >

- Assembly Services

More Than Just Parts

When thinking through how to arrange a manufacturing supply chain, the root decision comes down a fundamental question: Build or Buy?

No single company can excel at every task, so companies should focus their energies where they lead their field, and outsource the remainder to experts at those activities.

Companies that outsource with the right partners are able to access to specialized equipment and expertise, achieve cost savings, improve production efficiency, and streamline processes and their overall supply chain.

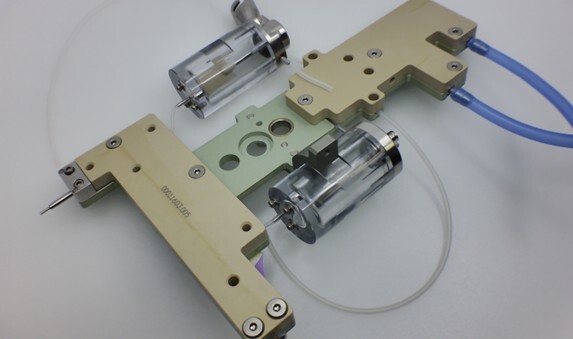

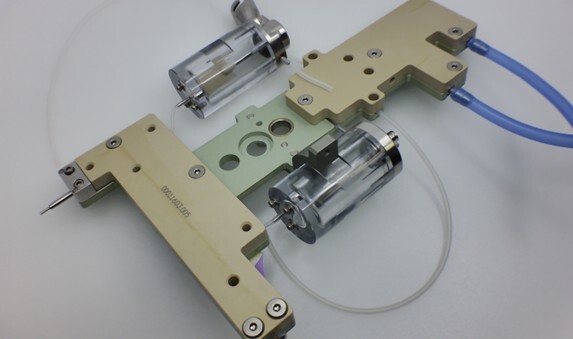

Click here for information about our Clean Room Assembly & Packaging Services.

EMI's ASSEMBLY SERVICES

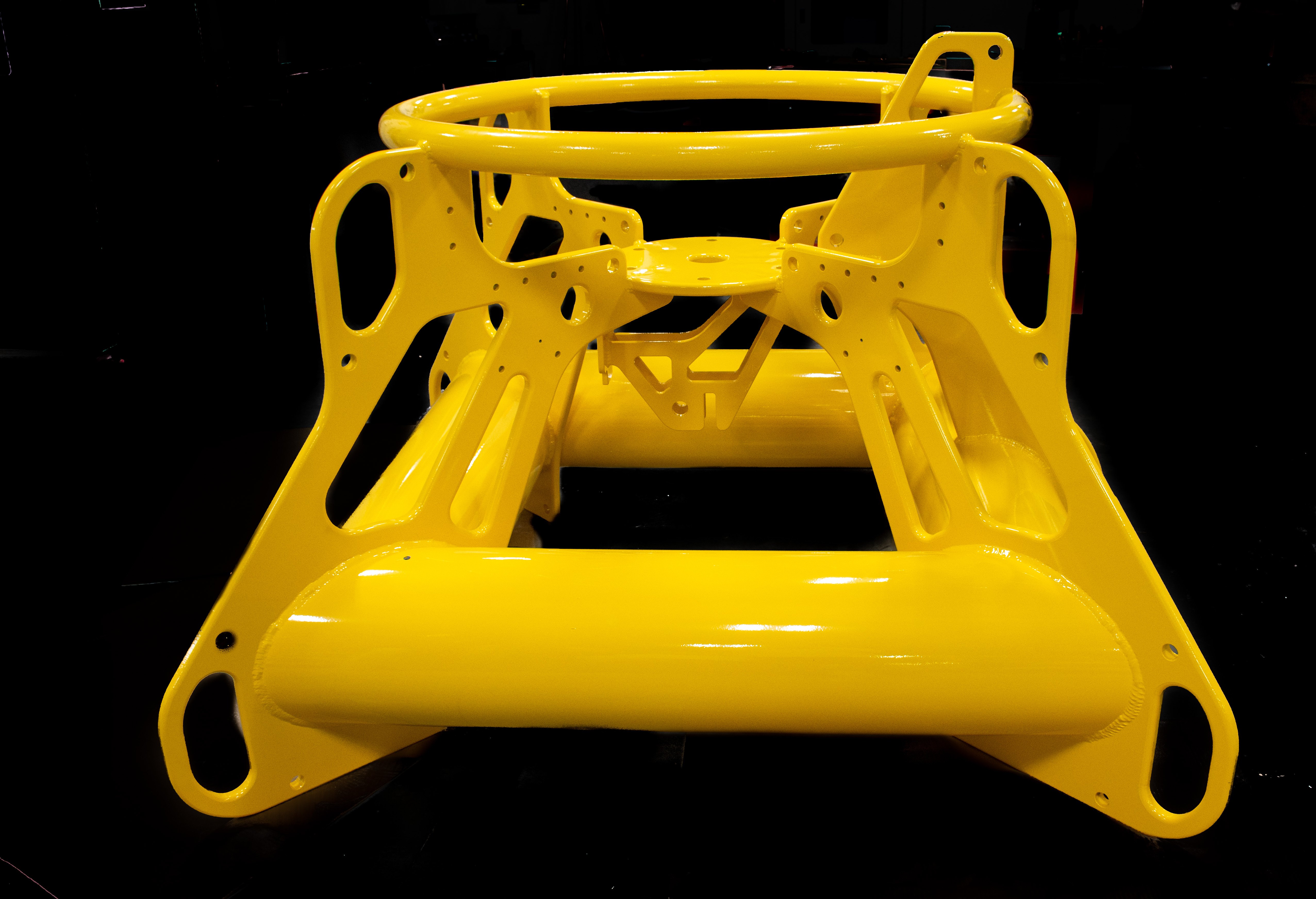

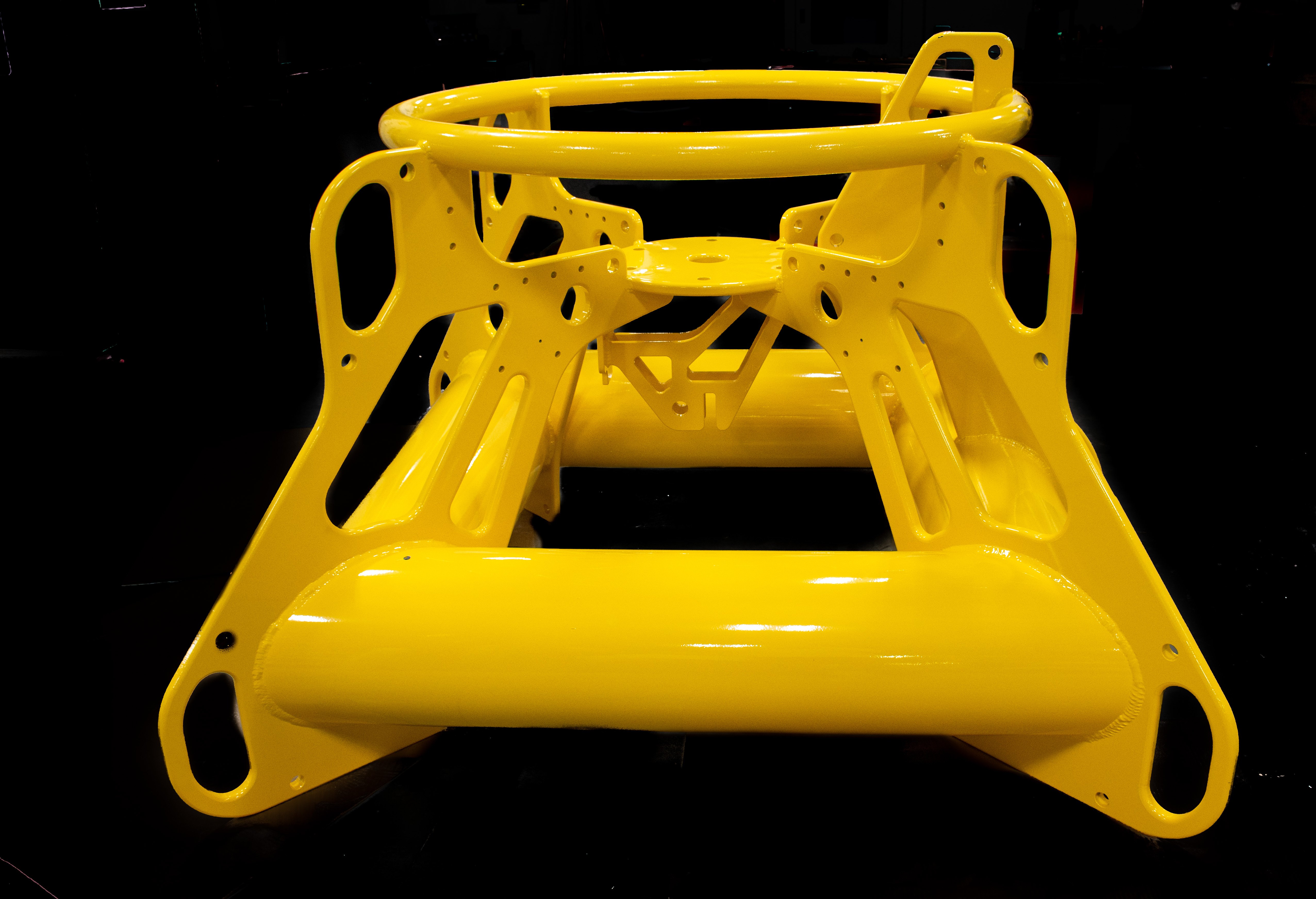

In service of our customer partners' goals, EMI can coordinate and manage anything from a simple helicoil placement to complex creations. Our services include:

TIPS FOR CHOOSING AN ASSEMBLY PARTNER

Because different companies have different strategic approaches to production, choosing the right outsourcing partner really means choosing the right relationship. Things to consider include:

Technical Capabilities

Choose a partner that has the right equipment and expertise with your chosen materials to achieve the dimensions and tolerances you need.

Certifications & Quality Assurance

Your partner should have 3rd party-verified credentials, such as ISO 9001, the right inspection equipment, and robust quality and documentation procedures they can share with you for each production run.

Production Capacity

Whether your volume needs are low or high, select a partner that has experience in handling a range of volumes and in flexibly managing changes when forecasts come in low.

Supply Chain Integration

The right production partner will fit seamlessly into and improve your overall supply chain.

Technical & Engineering Support

Products with increasing production quantities, including New Product Introductions (NPIs), can quickly outgrow the anticipated volumes forecast so work with a partner that bring DFM, DFA and the DF-Machinability expertise to the relationship.

Confidentiality and IP Management

The right partner will treat your sensitive business information, including Intellectual Property, with the care you deserve.

Experience & Stability

Choose a partner that has walked this road before.

Responsive and Accountable Service

Choose a partner that communicates pro-actively and owns (and fixes) mistakes when they inevitably occur.

Commitment to YOUR Success Over the Long-Term

Choose a partner that … actually wants to be your partner and builds a lasting relationship focused on delivering success for you.

Companies take advantage of EMI's Assembly services build supply chain resiliency and make their lives life simpler because they don't have to manage dozens of vendors.

If you would like to explore assembly outsourcing possibilities, please reach out to start the conversation.

Ready for a Conversation?

Testimonials

%20-%20Polymer%20Corp%201%20Light%20Green.png)

%20-%20Ocean%20Imaging%204%20Light%20Gray.png)

%20-%20Prior%20Scientific%204%20Light%20Red.png)

Why EMI?

Choosing the right outsourcing partner for your precision manufacturing needs can be the difference between success or failure for a given project. The question is how to choose.

The answer is to optimize for the right relationship. Choose a partner that supports your supply chain needs by delivering responsive service, open two-way communications, and on-time delivery.

For more than a half-century and continuing to this day, EMI always seeks to co-create the right relationship by prioritizing our partners' success.

Our Promise:

“More than Parts: Partnership.”

Contact us today to start building the right relationship.

%20Transparent%20Cropped.png?width=218&height=84&name=EMI%20Logo%20PNG%20(360%20x%20144%2072%20DPI)%20Transparent%20Cropped.png)