MARKING & ENGRAVING

- Home >

- Capabilities & Services >

- Marking & Finishing >

- Marking & Engraving

Part Marking - Goals and Techniques

Companies choose to mark their parts for many reasons, in pursuit of one or more specific business objectives.

In addition to the more obvious goals, such as branding, identification, and inventory management, additional reasons might also include quality control, regulatory compliance, traceability and anti-counterfeiting.

Whatever your reason, EMI can help you accomplish those goals using these techniques:

- Laser Marking

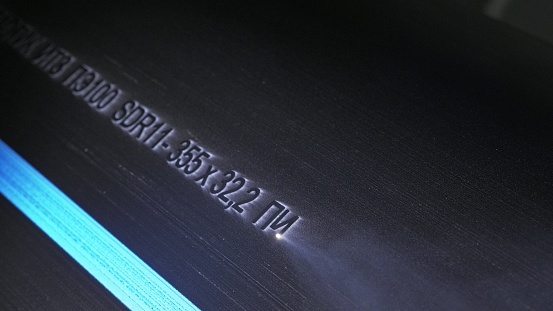

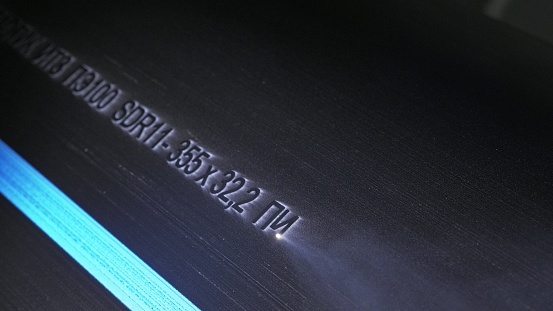

- Laser Engraving

- Electrochemical Etching

- Silk Screening

- Pad Printing

Choosing the Right Part Marking Solution

Matching the right marking solution for your precision machined parts and assemblies requires balancing several factors, including the:

- Material being marked

- Permanence of the mark

- Operating environment

- Shape and size of the area available for marking

- Volume of production

- Whether the mark will be visible on the final assembly

Another important consideration is whether the marking technique deforms or changes the part's dimensions in some way.

Stamping, for example, can be an inexpensive method, but is usually inappropriate for precision parts. Similarly, welding an identifying plate is a decades old solution but can introduced heat distortions, especially with delicate parts.

Laser engraving and electrochemical etching both remove some amount of material, which changes the measurable dimensions of the part. These methods, therefore, should only be selected for surfaces where these changes will not impact the part's performance.

Laser engraving removes material to create a textured mark to a depth you can choose, while laser marking typically only discolors the surface of the work piece without removing material.

As with laser marking, both silk screening and pad printing do not create dimensional changes for the machined part. Each of these techniques can be an excellent marking choice depending on the material and the other factors noted above.

Whatever your specific usage case, EMI can assist with selecting the right marking technique to help you accomplish your goals with confidence.

Reach out today to start the conversation about your next project.

Start a Conversation

Testimonials

%20-%20Ocean%20Imaging%201%20Light%20Blue.png)

%20-%20Paquette%20%26%20Assocs%203%20Light%20Gray.png)

%20-%20DTM%20Packaging%204%20Light%20Green.png)

Why EMI?

Choosing the right outsourcing partner for your precision manufacturing needs can be the difference between success or failure for a given project. The question is how to choose.

The answer is to optimize for the right relationship. Choose a partner that supports your supply chain needs by delivering responsive service, open two-way communications, and on-time delivery.

For more than a half-century and continuing to this day, EMI always seeks to co-create the right relationship by prioritizing our partners' success.

Our Promise:

“More than Parts: Partnership.”

Contact us today to start building the right relationship.

%20Transparent%20Cropped.png?width=218&height=84&name=EMI%20Logo%20PNG%20(360%20x%20144%2072%20DPI)%20Transparent%20Cropped.png)