CNC PRECISION TURNING

- Home >

- Capabilities & Services >

- CNC Machining >

- CNC Precision Turning

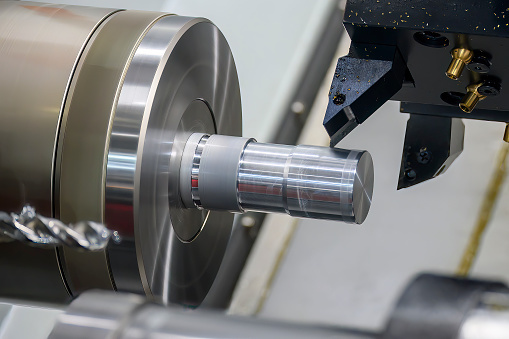

What Is CNC Precision Turning?

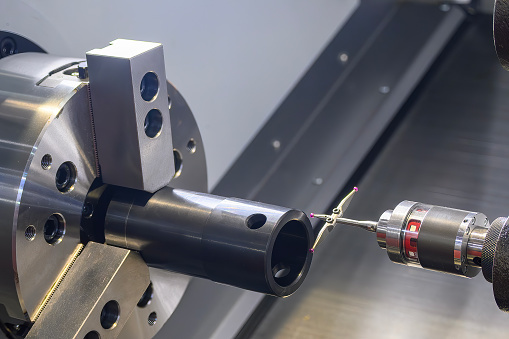

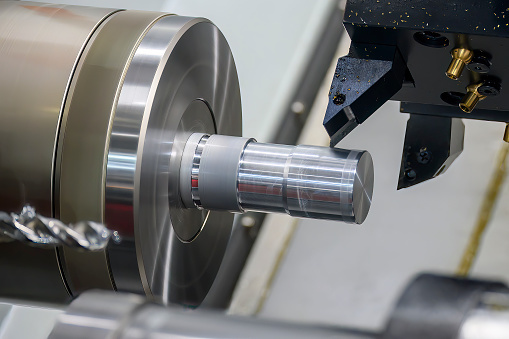

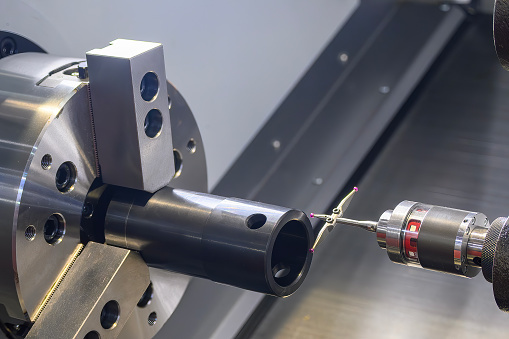

CNC (Computer Numerical Control) Turning is a subtractive manufacturing process that uses computer-controlled lathes to remove material from a rotating workpiece, creating precise and complex shapes. This method allows for high accuracy and repeatability in producing parts with tight tolerances, making it suitable for various industries.

Turning lathes perform these actions:

- Cutting

- Drilling

- Boring

- Facing

- Sanding

- Knurling

- Grooving

- Chamfering

- Parting

- Thread Cutting

- Taper Turning

- Eccentric Turning

Spindles & Turrets

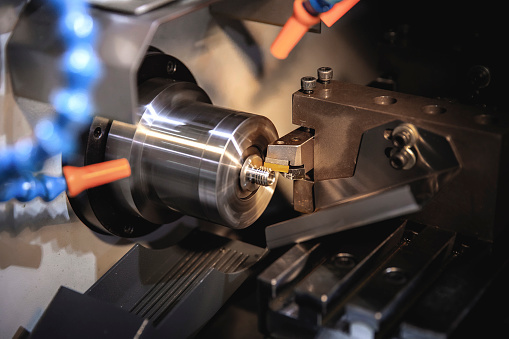

A lathe uses a spindle to hold and rotate the workpiece, which allows the cutting tool to remove material.

A turret holds multiple cutting tools and allows for rapid switching between tools which are held stationary against the workpiece to remove material. Some turrets themselves can move on multiple axes via CNC controls, giving greater freedom of motion for the cutting tool to create more complex shapes.

Advanced CNC turning machines can contain multiple spindles and multiple turrets which allows for very complex components to be machined with greater efficiency as both ends of the part can be worked on simultaneously.

EMI has more than a dozen CNC turning machines, some with multiple spindles and/or turrets and many with automatic bar feeders for automating long production runs. No matter the simplicity or complexity of your part, EMI can handle the job and will assign it to the appropriate machine to keep your costs low for any volume you need.

Our expertise allows us to machine parts with tolerances as tight as ±0.0001″ (±0.00254 mm).

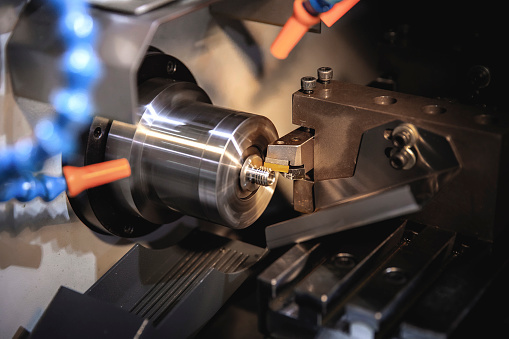

Mill-Turn Centers

EMI's roster also includes a range of machines that combine both milling and turning.

As you might imagine, mill-turn centers include both milling and turning operations. Milling uses a rotating cutting tool on the workpiece, while with turning the cutting surface does not rotate.

The benefits of using a mill-turn machine are shorter cycle times, reduced material handling and increased precision for parts that require both operations.

EMI can select from more than a half dozen mill-turn centers on our floor to complete your complicated parts quickly and efficiently.

Horizontal and Vertical Turning Lathes

As with milling machines, the lathe spindles can be oriented either horizontally or vertically. Horizontal lathes are better suited for working on longer, thinner, higher production parts, while vertical tuning machines are preferred for larger and heavier workpieces where gravity can be used to help clamp it in place.

EMI has both horizontal and vertical turning machines so we can bring the right machine to bear to complete your project on time and on budget.

Contact Us to start the conversation about your next project.

EMI's Turning Equipment

EMI has 13 turning machines on our floor and a further five mill-turn centers. We can turn parts up to 24" in diameter for 70" in length, and up to 19" in diameter for 80" in length.

EMI's Lathes

(2) NAKAMURA-TOME SC250 ... w/ LNS Bar Feeder

(2) NAKAMURA-TOME TMCD-15

(1) NAKAMURA-TOME TMC 15 ... w/ Spego Turnamic 126 Bar Feed

(1) YCM TC 36W

(1) DMG MORI EcoTurn 450

(1) SHARP 1880-80" ... w/ Newall Readout

(2) TRAK 2460 24'' Lathe

(1) WEBB 17" ... w/ Digital Readout

(2) BRIDGEPORT EZ Path

Mill-Turn Machines

(1) NAKAMURA WT300 ... w/ LNS Bar Feeder

(1) NAKAMURA WT150 ... w/ LNS Bar Feeder

(2) DMG MORI NLX 2500

(1) DMG MORI NLX 2500 / 1250 ... w/ Steady Rest

(1) DMG MORI NLX 2000

(1) YCM Supermax GT300M

For a complete list please visit our Equipment & Facilities page.

Materials EMI Turns

Ferrous Metals

- Iron

- Stainless Steel

- Carbon Steel

- Low-Carbon Steel

- Hot Rolled Steel

- Cold Rolled Steel

- Tool Steel

Non-Ferrous Metals

- Aluminum

- Brass

- Bronze

- Copper

- Copper Moly

- Molybdenum

- Nickel

Exotic Metals

- AlBeMet

- Copper Tungsten

- Inconel

- Invar

- Kovar

- Monel

- Phosphor Bronze

- Tellurium Copper

- Titanium

Plastics & Composites

- ABS

- CPVC

- HDPE

- LDPE

- PA (Nylon)

- PC (Polycarbonate, Lexan)

- PE (Polyethylene)

- PEEK

- PEI (Ultem)

- PET / PETE / PET-P (Ertalyte)

- PMMA (Acrylic, Plexiglass)

- POM (Acetal, Delrin)

- PP / PPO (Polypropylene)

- PPE (Noryl)

- PPSU (Radel)

- PS

- PTFE (Teflon)

- PVC

- UHMW-PE

- CFRP (Carbon Fiber Reinforced Polymers)

- GFRP (Glass Fiber Reinforced Polymers)

- MMCs (Metal Matrix Composites)

- CMCs (Ceramic Matrix Composites)

For a complete list please visit our Materials page.

Got an Urgent Job?

Testimonials

%20-%20Ocean%20Imaging%202%20Light%20Gray.png)

%20-%20Harmonic%20Drive%204%20Light%20Green.png)

%20-%20Prior%20Scientific%201%20Light%20Blue.png)

Why EMI?

Choosing the right outsourcing partner for your precision manufacturing needs can be the difference between success or failure for a given project. The question is how to choose.

The answer is to optimize for the right relationship. Choose a partner that supports your supply chain needs by delivering responsive service, open two-way communications, and on-time delivery.

For more than a half-century and continuing to this day, EMI always seeks to co-create the right relationship by prioritizing our partners' success.

Our Promise:

“More than Parts: Partnership.”

Contact us today to start building the right relationship.

%20Transparent%20Cropped.png?width=218&height=84&name=EMI%20Logo%20PNG%20(360%20x%20144%2072%20DPI)%20Transparent%20Cropped.png)