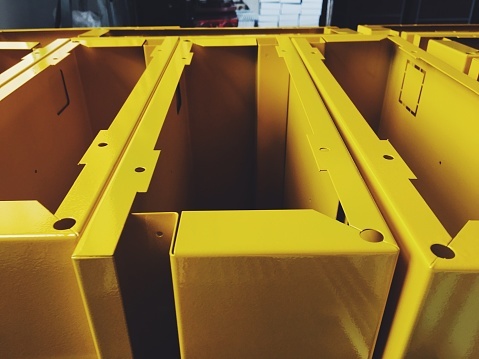

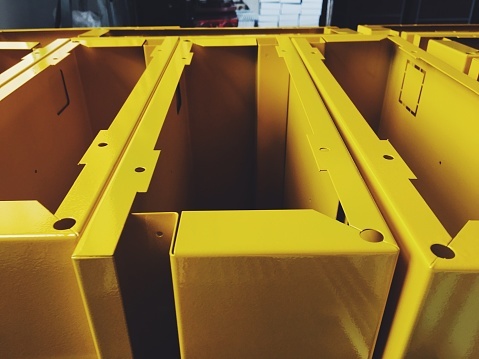

SURFACE FINISHING

Plating, Painting, Anodizing & Much More

- Home >

- Capabilities & Services >

- Marking & Finishing >

- Surface Finishing

It's Called Finishing for a Reason

Once your parts and components are Precision Machined and pass through Quality Assurance EMI can perform a wide range of activities to get them to the desired end state properties, appearance and performance.

There are numerous reasons to perform finishing activities on parts, such as:

- Preventing Corrosion

- Improving Durability and Wear

- Modifying Lubricity

- Enhancing or Reducing Electrical Conductivity

- Improving Aesthetic Appearance

- Increasing Hardness

- Altering Emissivity

- Promoting Adhesion

- Preventing Galling

- Smoothing Rough Edges

EMI's surface finishing treatments fall into two general categories:

- Mechanical Finishing

- Chemical Finishing

Mechanical Finishing

Mechanical finishing involves using one or more processes to physically alter the surface of a material. Unlike chemical treatments, mechanical finishing uses physical forces like abrasion, pressure, or friction to accomplish the goal.

Some of EMI's mechanical finishing methods include:

- Deburring

- Sanding

- Tumbling

- Polishing

- Media Blasting

- Passivation

- Grinding, Honing & Lapping

Chemical Finishing

Chemical finishing uses controlled chemical reactions to create a protective layer on or alter the surface of the part.

Additive Chemical Finishing

Certain chemical finishing processes are additive, applying a layer of material to the base part. Examples include electroplating, anodizing (Types II and III), conversion coatings, paint and powder coating.Subtractive Chemical Finishing

Some chemical finishing processes are extractive, removing ions and molecules to achieve the desired end state. A good example of this is pickling.Neither Additive nor Subtractive

A subset of chemical finishing methods results in essentially no dimensional change. These are passivation, electropolishing and Type I chromic acid anodizing, chem films including alodine and other specialized processes like tiodize.

Chemical Finishing Methods

A partial list of EMI's chemical finishing methods includes:

- Electropolishing

- Electrolytic & Electroless Plating

- Anodizing

- Pickling

- Passivation

- Chem Films

- Conversion Coatings

- Black Oxide

- Phosphating

- Paint

- Powder Coating

- Vapor Honing

Of course, if you need a specialty coating and you don't see it above chances are good that we can make it happen for you, so please reach out and get EMI on the job for you.

A Final Word About Surface Finishing

It's the final result that matters.

Sometimes we find engineers and part designers may not know all the options for combining machining and surface finishing.

That's why EMI offers Engineering Support as one of our Value Added Services.

Whether your project requires mechanical surface finishing, chemical surface finishing, or both, in all cases EMI will use the best combination of machining and finishing to achieve the final tolerances required.

If you would like to talk through some machining and surface finishing options for your next project, reach out today.

Got an Urgent Job?

Testimonials

%20-%20DTM%20Packaging%205%20Light%20Blue.png)

%20-%20Prior%20Scientific%202%20Light%20Green.png)

%20-%20Ocean%20Imaging%205%20Light%20Gray.png)

Why EMI?

Choosing the right outsourcing partner for your precision manufacturing needs can be the difference between success or failure for a given project. The question is how to choose.

The answer is to optimize for the right relationship. Choose a partner that supports your supply chain needs by delivering responsive service, open two-way communications, and on-time delivery.

For more than a half-century and continuing to this day, EMI always seeks to co-create the right relationship by prioritizing our partners' success.

Our Promise:

“More than Parts: Partnership.”

Contact us today to start building the right relationship.

%20Transparent%20Cropped.png?width=218&height=84&name=EMI%20Logo%20PNG%20(360%20x%20144%2072%20DPI)%20Transparent%20Cropped.png)