CNC PRECISION GRINDING, HONING & LAPPING

- Home >

- Capabilities & Services >

- CNC Machining >

- CNC Precision Grinding, Honing & Lapping

What Is CNC Precision Grinding, Honing & Lapping?

Grinding, honing and lapping are abrasive manufacturing processes used to refine the surface profile of a workpiece.

CNC (Computer Numerical Control) machines that perform these processes are able to achieve precision results that meet the desired surface characteristics specifies by our customer partners' engineers.

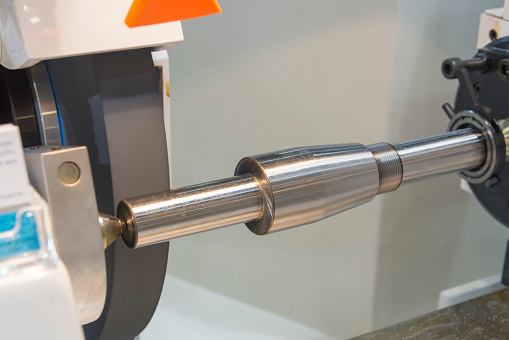

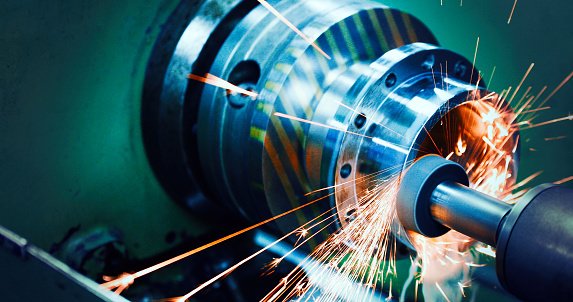

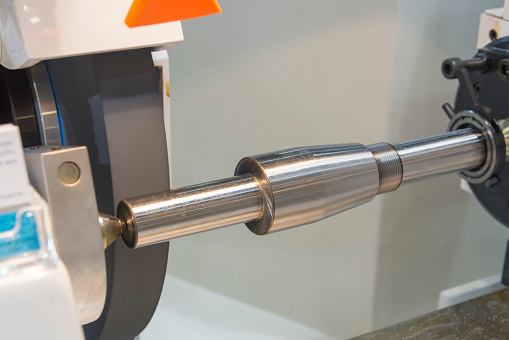

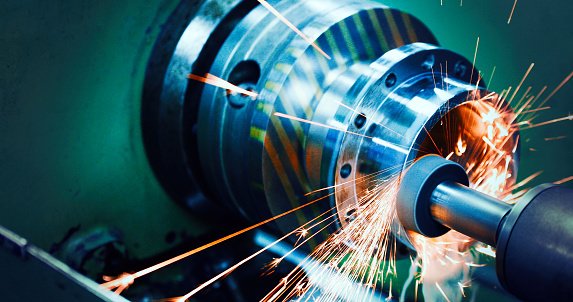

GRINDING

Grinding employs a rotating abrasive wheel to remove material from the surface of a flat or contoured workpiece. EMI's CNC grinding machines can be used for either roughing or for final finishing depending on the final surface roughness you need.

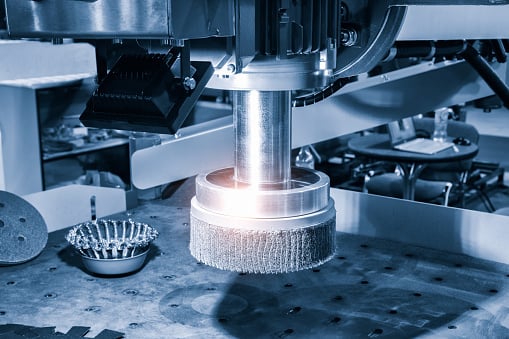

HONING

Honing is generally associated with finishing bores and cylinders and involves abrading a surface to improve the geometric form and dimensional accuracy of a cylindrical part's surface or even create a specific finish itself.

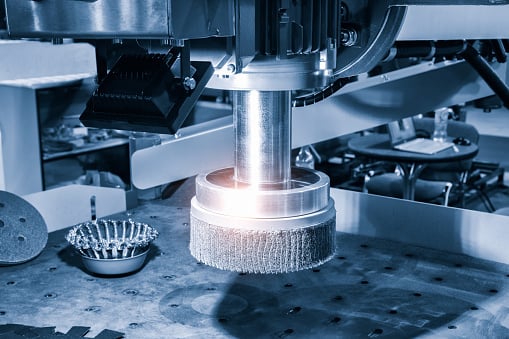

LAPPING

Lapping is a precision finishing process that uses loose abrasive particles suspended in a fluid to remove material and create a smooth, flat surface on a workpiece and is used to achieve extremely tight tolerances for flatness, surface finish, and parallelism.

EMI brings decades of experience to machining the right surface profile for your parts.

Our expertise allows us to machine parts with tolerances as tight as ±0.0001″ (±0.00254 mm) and achieve surface roughness to 8 Ra and #4 finish for grained direction parts.

EMI's Grinding, Honing & Lapping Equipment

EMI can precision grind both flat and cylindrical surfaces, including both outer and inner diameters.

EMI can precision hone in both horizontal and vertical orientations.

- Okamoto Surface Grinder

- Harig Super 618 Surface Grinder

- Norton OD Grinder

- Dumore ID Grinder

- Sunnen Automatic Horizontal Honing Machine

- Sunnen Automatic Vertical Honing Machine

For a complete list please visit our Equipment & Facilities page.

Materials EMI Grinds, Hones & Laps

Ferrous Metals

- Iron, Stainless Steel, Carbon Steel, & more

Non-Ferrous Metals

- Aluminum, Brass, Molybdenum, Nickel & more

Exotic Metals

- AlBeMet, Inconel, Kovar, Monel, Titanium & more

Plastics & Composites

- ABS, Lexan, Ultem, Ertalyte, Delrin, Noryl, Radel, PVC, UHMW-PE, CFRP, GFRP, MMCs, CMCs & more

For a complete list please visit our Materials page.

Got an Urgent Job?

Testimonials

%20-%20DTM%20Packaging%205%20Light%20Gray.png)

%20-%20Harmonic%20Drive%204%20Light%20Blue.png)

%20-%20Paquette%20%26%20Assocs%207%20Light%20Red.png)

Why EMI?

Choosing the right outsourcing partner for your precision manufacturing needs can be the difference between success or failure for a given project. The question is how to choose.

The answer is to optimize for the right relationship. Choose a partner that supports your supply chain needs by delivering responsive service, open two-way communications, and on-time delivery.

For more than a half-century and continuing to this day, EMI always seeks to co-create the right relationship by prioritizing our partners' success.

Our Promise:

“More than Parts: Partnership.”

Contact us today to start building the right relationship.

%20Transparent%20Cropped.png?width=218&height=84&name=EMI%20Logo%20PNG%20(360%20x%20144%2072%20DPI)%20Transparent%20Cropped.png)