SCIENTIFIC INSTRUMENTS, TESTING & METROLOGY

Precision Machining, Extreme Accuracy, Dependability

- Home >

- Industries >

- Scientific Instruments, Testing & Metrology

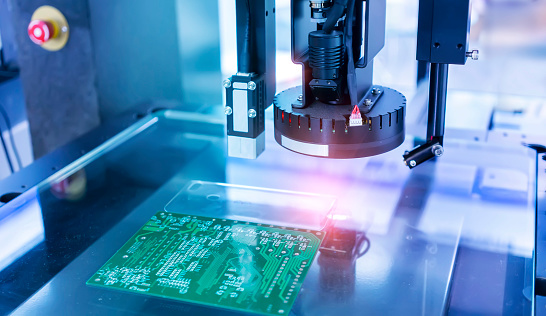

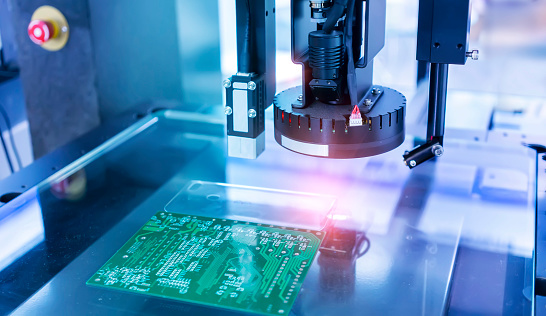

Outsourced Manufacturing for Scientific Instruments, Testing & Metrology

Companies in a vast number of industries, including Medical & Life Sciences, Defense, Optical Instruments & Photonics, Motion Control & Automation, Semiconductor Equipment & Tooling and many more, cannot function without dependable high precision tools to verify their output.

In turn, companies in the Scientific Instruments, Testing & Metrology space rely on EMI's high precision machining capabilities and decades of knowhow to create their own products.

Scientific Instruments, Testing & Metrology Industry Applications

With decades of precision machining experience and more than 40 CNC machines, including automated 5-axis mill-turn centers, EMI consistently delivers the quality and ultra-high precision components that Motion Control and Automation companies need to build the tools that so many other industries rely on.

End Use Products

- Video measuring systems

- Coordinate measuring machines

- Industrial microscopy

- Laser, radar, lidar & other measuring systems

- Optical sensing systems

- Optical measuring, profilometers & comparators

- Precision measuring tools

- Drive technologies

- Positioning systems

- Electrical & mechanical drives

- Motion controllers

- Automation technology

- Torque control & testing systems

- Hardness testing systems

- Torsion testing systems

- Tensile testing systems

- Compression testing systems

Example Parts We Create

- Hydraulics

- Pneumatics

- Manifolds

- Servo motors & amplifiers

- Lasers

- AC drives

- Variable frequency drives

- Converters

- Motors

- Positioners

- Sensors

- Valves

- Solenoids

- Actuators

- Mounting plates

- Adapters

Custom Manufacturing Process, Materials & Surface Treatments

Manufacturing Processes

To support an endless array of manufacturing goals, Scientific Instruments, Testing & Metrology manufacturers' needs are as diverse as the day is long. Here are some of the services we provide:

(click each for info about part sizes, weights and tolerances)

Click here to learn more about EMI's Manufacturing Processes.

Materials

Scientific Instruments, Testing & Metrology industry designers specify a huge range of metallic, plastic and composite materials. EMI is capable of machining a great many of these, including (but not limited to):

- Stainless Steel & Carbon Steel

- Titanium

- Aluminum

- Molybdenum

- Specialty alloys (AlBeMet, Hastelloy, Invar, Kovar, etc.)

- Plastics (PEEK, Delrin, Ultem, etc.)

- Composites (Fiberglass Laminates, Carbon and Glass Fiber Reinforced Polymers, Metal and Ceramic Matrix Composites)

Click here for a more complete list of Materials EMI can machine for you.

Surface Treatments

For Surface Finishing, whether your needs are tactile, emissivity control, lubricity, conductivity, corrosion resistance, color or something else, EMI delivers a diverse range of finishing solutions:

- Anodizing

- Electroplating

- Electroless Plating

- Passivation

- Chem Films

- Laser Marking, Silk Screening, Pad Printing

- Paint, Powder Coating

- Deburring

- Media Blasting

- Knurling

- Polishing

Our capabilities include surface roughness to 8 Ra and #4 finish for grained direction parts.

Click here for a more info about EMI's Surface Finishing options.

Got an Urgent Job?

Value-Added Services

For those Scientific Instruments, Testing & Metrology industry partners needing further support, EMI offers several value-added services:

- Assembly

- Design for Manufacturing Advisory Support

- Scaling Manufacturing Volume Advisory

- Inventory / Stock Management

- Vendor Transition Support

Click here to see EMI's range of Value Added Services.

Quality Considerations

EMI is ISO 9001:2015 certified and ITAR registered, so quality assurance is built into everything we do. Using the latest testing and metrology equipment EMI performs in-process and finished article inspection, testing and verification activities our temperature controlled quality lab. And we provide traceability documentation and results certification as dictated by our customers business and regulatory needs.

Click for more info about Quality Assurance.

Responsive Service & Support

It takes great service and support to deliver the results our customer's customers deserve. In order to serve you best EMI delivers highly responsive service and open two-way communications backed by a relentless focus on on-time delivery to support your supply chain needs.

"More than Parts: Partnership." is our brand promise and it drives everything we do to serve you.

Testimonials

/IDE%20(NO%20NAME%20USAGE)%20Testimonial%20Block%203/Testimonial%20Panel%20(350%20x%20350)%20-%20IDE%203%20Light%20Blue.png)

Why EMI?

Choosing the right outsourcing partner for your precision manufacturing needs can be the difference between success or failure for a given project. The question is how to choose.

The answer is to optimize for the right relationship. Choose a partner that supports your supply chain needs by delivering responsive service, open two-way communications, and on-time delivery.

For more than a half-century and continuing to this day, EMI always seeks to co-create the right relationship by prioritizing our partners' success.

Our Promise:

“More than Parts: Partnership.”

Contact us today to start building the right relationship.

%20Transparent%20Cropped.png?width=218&height=84&name=EMI%20Logo%20PNG%20(360%20x%20144%2072%20DPI)%20Transparent%20Cropped.png)