CNC WIRE EDM

- Home >

- Capabilities & Services >

- CNC Machining >

- CNC Wire EDM

What Is CNC Wire EDM?

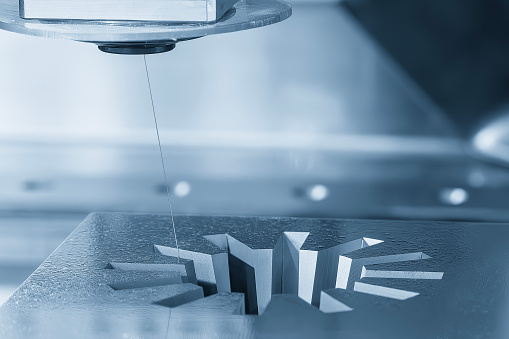

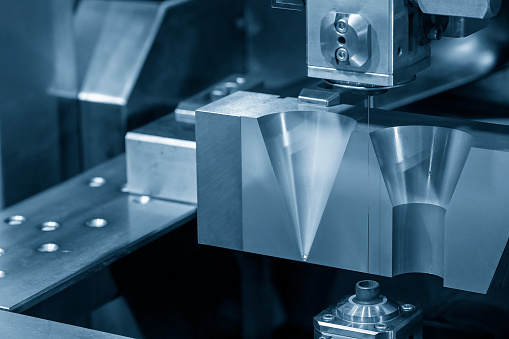

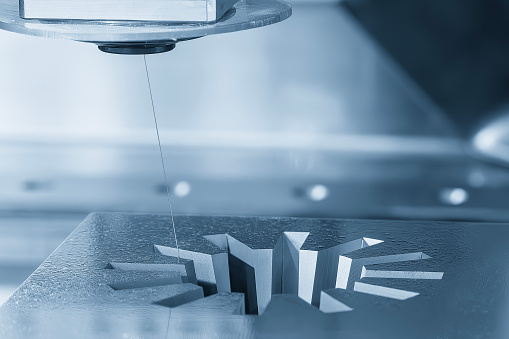

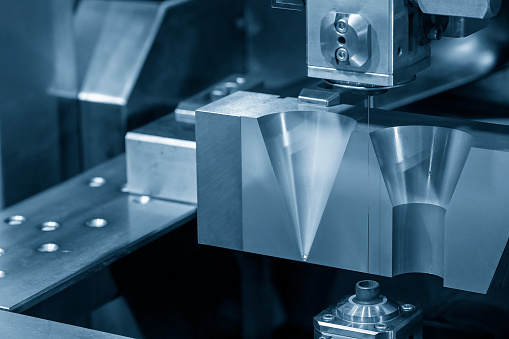

Wire EDM, or Electrical Discharge Machining, is a machining process that uses a thin wire filament and voltage to cut conductive materials, achieving exceptional dimensionally accurate results.

The electrically grounded part and the charged wire are placed in a dielectric liquid, such as deionized water. When the CNC motion-controlled part nears the wire, tiny electrical sparks jump the gap and erode the material into the desired shape as programmed. The dielectric liquid cools the part and carries away small debris.

CNC Wire EDM can achieve extremely tight tolerances and complex geometries and, because the wire never directly contacts the workpiece, stress and deformation are minimized.

If you are designing parts that need this, please contact us and start the conversation.

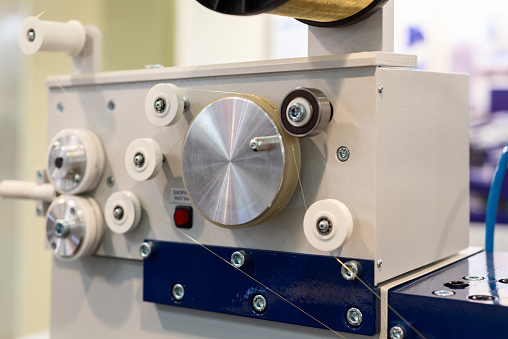

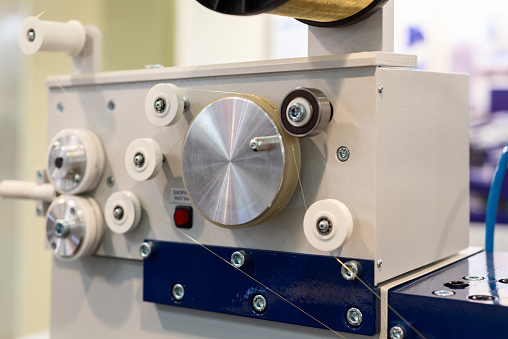

EMI's Wire EDM Equipment

- Sodick VL400Q wire EDM

- Sodick VL600QH wire EDM 19.6 height capacity

For a complete list please visit our Equipment & Facilities page.

Materials EMI Wire EDMs

The list of materials we cut in our wire EDM machines includes:

- Aluminum

- Brass

- Bronze

- Copper

- Iron

- Steel

- Stainless Steel

- Tool Steel

- Titanium

For a complete list please visit our Materials page.

Got an Urgent Job?

Testimonials

%20-%20Ocean%20Imaging%201%20Light%20Green.png)

%20-%20DTM%20Packaging%204%20Light%20Gray.png)

%20-%20Harmonic%20Drive%204%20Light%20Red.png)

Why EMI?

Choosing the right outsourcing partner for your precision manufacturing needs can be the difference between success or failure for a given project. The question is how to choose.

The answer is to optimize for the right relationship. Choose a partner that supports your supply chain needs by delivering responsive service, open two-way communications, and on-time delivery.

For more than a half-century and continuing to this day, EMI always seeks to co-create the right relationship by prioritizing our partners' success.

Our Promise:

“More than Parts: Partnership.”

Contact us today to start building the right relationship.

%20Transparent%20Cropped.png?width=218&height=84&name=EMI%20Logo%20PNG%20(360%20x%20144%2072%20DPI)%20Transparent%20Cropped.png)