CNC PRECISION MILLING

- Home >

- Capabilities & Services >

- CNC Machining >

- CNC Precision Milling

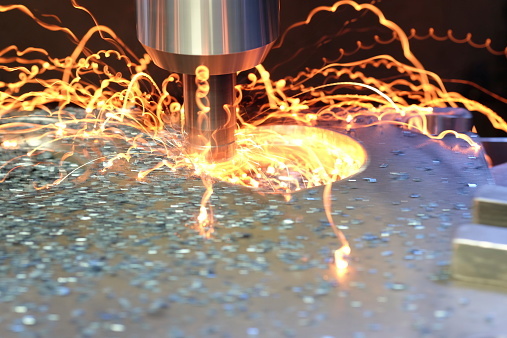

What Is CNC Precision Milling?

CNC (Computer Numerical Control) Milling is a subtractive manufacturing process, where a computer-controlled milling machine uses rotating cutting tools to remove material from a workpiece to create a desired shape. Aspects of CNC Milling include:

- Highly automated process

- Highly consistent and repeatable

- Multiple-axis control

- Suitable for a wide range of materials, including metals, plastics and composites

Multi-Axis Control

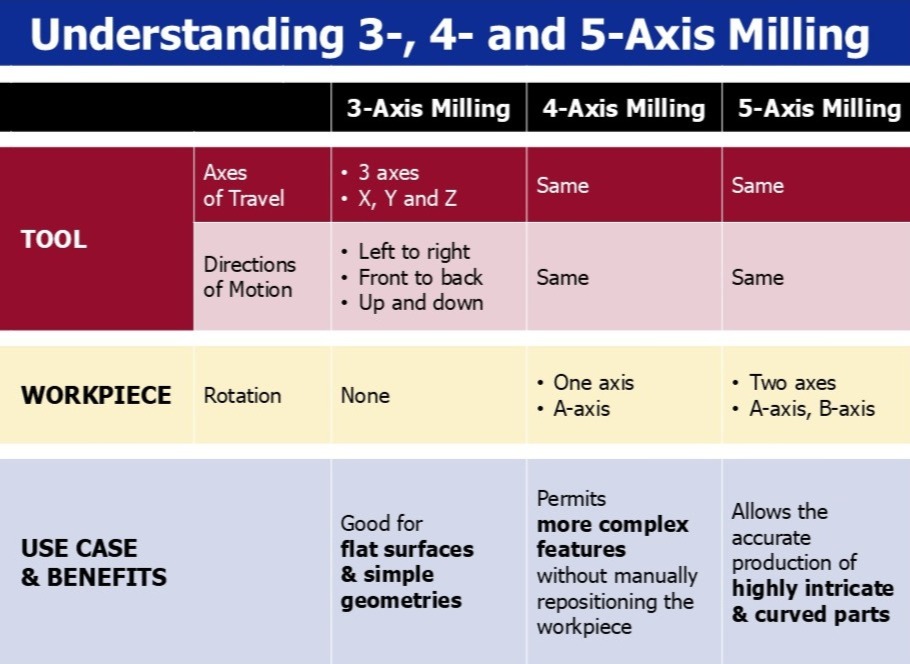

In the industry we commonly talk about 3-axis, 4-axis and 5-axis machines, which can cause a bit of confusion.

The term 'axis' refers to how either the tool or the workpiece is capable of moving.

The chart below gives a quick overview of the differences.

3-Axis Milling

Means the workpiece is held steady while the tool can travel in three directions of motion (left to right, front to back, up and down) called X, Y, and Z axes. 3-axis milling is suited for flat surfaces & simple geometries.

4-Axis Milling

Means the tool can move along the three X, Y and Z axes, while the workpiece rotates around one axis, called the A-axis, at the same time. 4-axis milling permits more complex features without manually repositioning the workpiece.

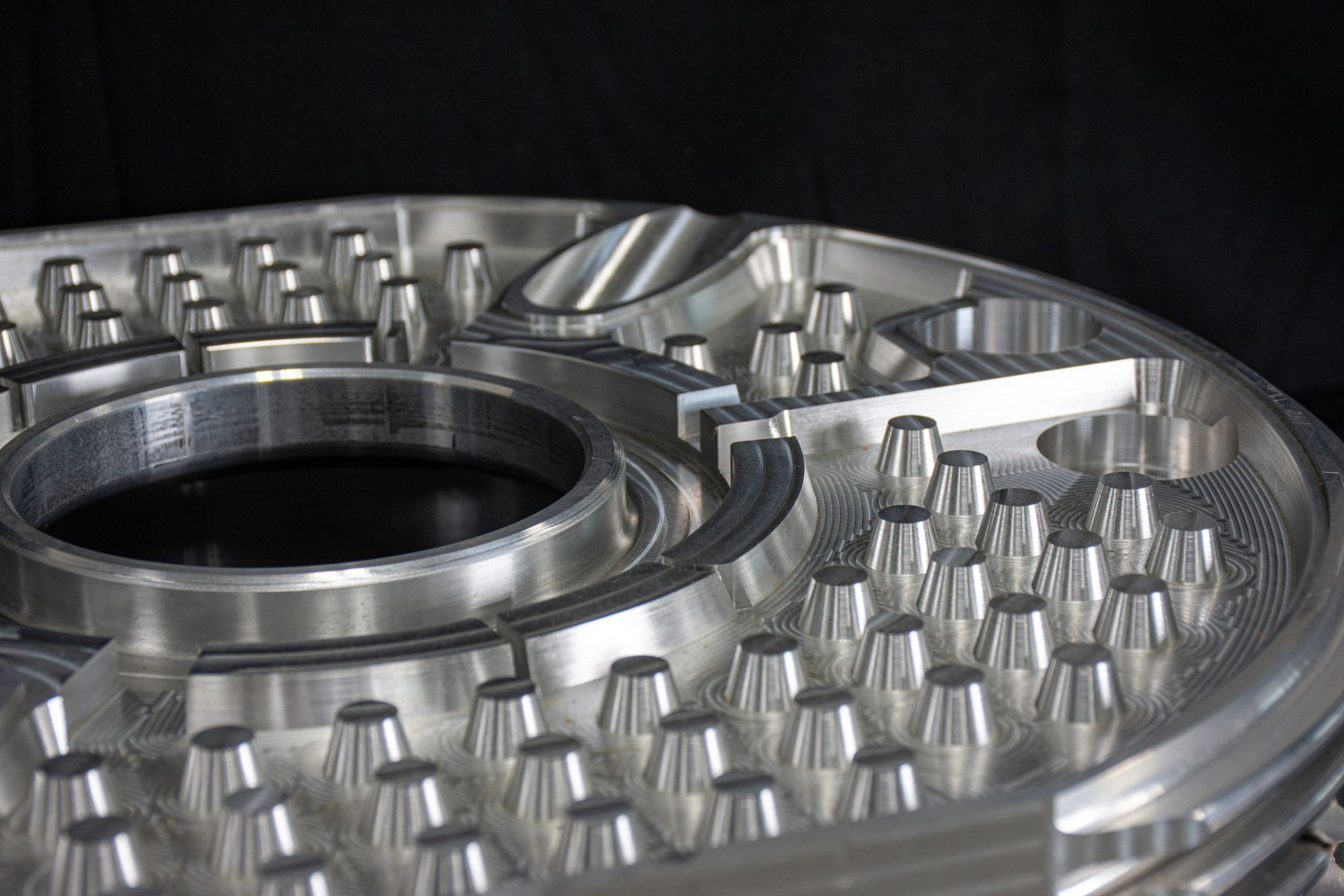

5-Axis Milling

In 5-axis milling Means the tool can travel along the three X, Y and Z axes, and the workpiece can rotate simultaneously on two axes, called the A and B axes. This allows the production of highly intricate and curved parts with great accuracy.

EMI's stable of more than two dozen milling machines includes 3-, 4- and 5-axis CNC machines, many of which feature pallet systems for automating long production runs with tolerances as tight as ±0.0001″ (±0.00254 mm).

No matter the simplicity or complexity of your part, EMI can handle the job and will assign it to the appropriate machine to keep your costs low for the volume you need.

Mill-Turn Centers

EMI's roster also includes a range of CNC machines called Mill-Turn Centers.

As you might imagine, these combine both milling and turning operations. Milling uses a rotating cutting tool on the workpiece, while with turning the cutting surface does not rotate.

Benefits of CNC Mill-Turn Centers

There are several benefits of using a mill-turn machine, including:

Speed & Efficiency

- Shorter setup

- Faster production cycle times

- Streamlined processes through multitasking

Accuracy & Precision

- Improved part quality

- Tighter tolerances

- Decreased error potential through reduced handling setups

Versatility & Complexity

- More complex parts

- A wider range of operations performed on the same workpiece

- Increased rage of materials can be machined

Cost Savings

- Reduced setup & takedown time

- Reduced spindle & labor time

- Lower tooling costs

EMI can select from more than a half dozen mill-turn centers on our floor to complete your complicated parts quickly and at the lowest cost.

Horizontal & Vertical Mills

Depending on the orientation of the spindle and cutting tools, mills can be classified as their horizontal or vertical.

Horizontal Mills

Horizontal mills generally are used for:

- Larger and heavier parts

- Applications that require a large about of material to be removed from the workpiece

- Larger production volumes

Vertical Mills

Vertical mills are used for:

- Smaller and lighter pieces

- Workpieces that require more precise cuts

- Shorter production runs

Because EMI has both horizontal and vertical mills, we can bring the right machine to bear to complete your project on time and on budget.

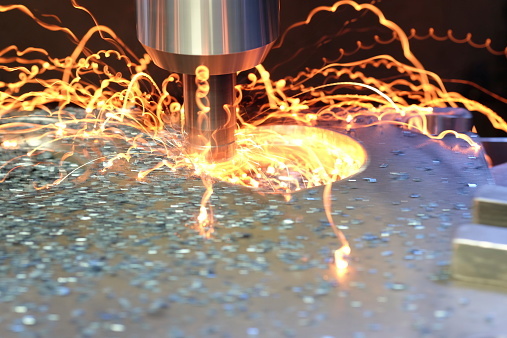

Face Milling & End Milling

Face Milling

Face milling, which rapidly and efficiently removes material from flat surfaces, is typically used with horizontal mills.

End Milling

Generally run on vertical milling machines, end milling is used to make complex geometries such as slots, pockets, grooves, and profiles.

Depending on your project, EMI might choose to use face milling or endmilling operations to get the job done efficiently and cost effectively.

Ready for a Conversation?

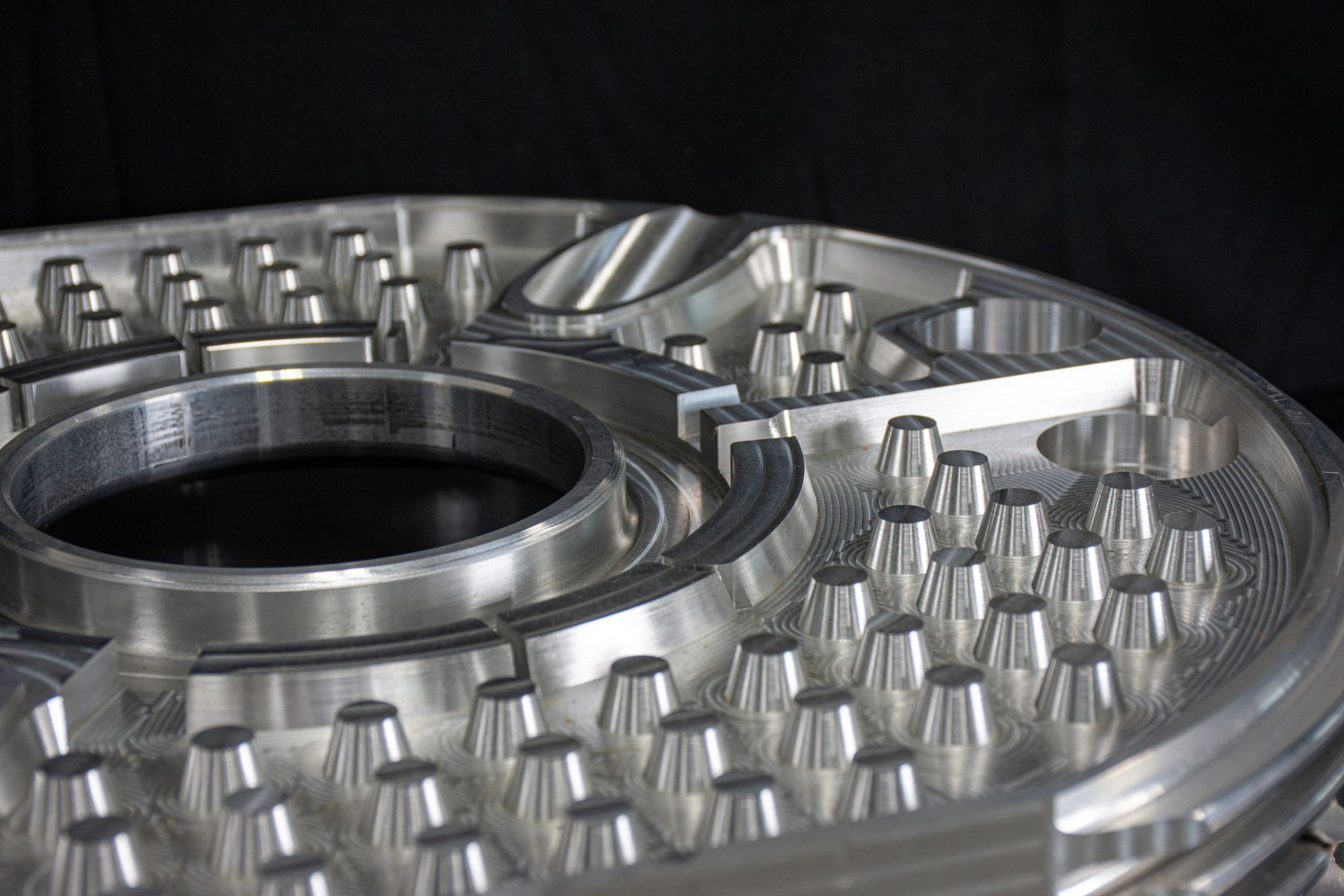

EMI's Milling Equipment

EMI has nearly 30 milling machines on our floor and a further five mill-turn centers. For CNC Machining with 5-Axis Capability we can machine parts up to 30" cubed. For CNC Machining with 4-Axis Capability we can machine parts up to 34" x 64".

5-Axis Milling

(4) DMG MORI DMU50 5 AXIS ... one w/ 10 pallet system

(1) DMG MORI DMU75 5 AXIS

(1) DMG MORI DMC75 5 AXIS ... w/ 3 pallet system

(1) ROBODRILL (alpha) - D21LiB5ADV - 5 Axis

(1) ROBODRILL (alpha) - D21LiB5ADV Plus - 5 Axis

4-Axis & 3-Axis Milling

(1) SUPERMAX NSV 156 A

(1) SUPERMAX NSV 102 A

(1) SUPERMAX NXV 1680A

(1) SUPERMAX MV 76A

(2) SUPERMAX NXV 1020A

(1) SUPERMAX XV 1250A

(1) SUPERMAX XV 1020A

(2) MAZAK HCN-5000 Horizontal Center ... w/ 24 pallet system

(1) MAZAK HCN-4000 Horizontal Center ... w/ 6 pallet system

(1) FANUC ROBODRILL (alpha) - T24iEL w/ pallet

(1) FANUC ROBODRILL (alpha) - D21MiA5 w/ 4th Axis

(1) FANUC ROBODRILL (alpha) - Ti4iD w/ 4th Axis

(1) FANUC ROBODRILL (alpha) - Ti4iD

(1) YCM NSV120A w/ 4th axis

(3) TRAK DPM BED MILL

(1) ACU-RITE MILL

(2) BRIDGEPORT rapid feed w/ digital readout

Mill-Turn Machines

(1) NAKAMURA WT300 ... w/LNS Bar Feeder

(1) NAKAMURA WT150 ... w/LNS Bar Feeder

(2) DMG MORI NLX 2500

(1) DMG MORI NLX 2500 / 1250 ... w/ Steady Rest

(2) DMG MORI NLX 2000

(1) YCM Supermax GT300M

For a complete list please visit our Equipment & Facilities page.

Materials EMI Mills

Ferrous Metals

- Iron

- Stainless Steel

- Carbon Steel

- Low-Carbon Steel

- Hot Rolled Steel

- Cold Rolled Steel

- Tool Steel

Non-Ferrous Metals

- Aluminum

- Brass

- Bronze

- Copper

- Copper Moly

- Molybdenum

- Nickel

Exotic Metals

- AlBeMet

- Copper Tungsten

- Inconel

- Invar

- Kovar

- Monel

- Phosphor Bronze

- Tellurium Copper

- Titanium

Plastics & Composites

- ABS

- CPVC

- HDPE

- LDPE

- PA (Nylon)

- PC (Polycarbonate, Lexan)

- PE (Polyethylene)

- PEEK

- PEI (Ultem)

- PET / PETE / PET-P (Ertalyte)

- PMMA (Acrylic, Plexiglass)

- POM (Acetal, Delrin)

- PP / PPO (Polypropylene)

- PPE (Noryl)

- PPSU (Radel)

- PS

- PTFE (Teflon)

- PVC

- UHMW-PE

- CFRP (Carbon Fiber Reinforced Polymers)

- GFRP (Glass Fiber Reinforced Polymers)

- MMCs (Metal Matrix Composites)

- CMCs (Ceramic Matrix Composites)

For a complete list please visit our Materials page.

Got an Urgent Job?

Testimonials

%20-%20Prior%20Scientific%202%20Light%20Blue.png)

%20-%20Paquette%20%26%20Assocs%201%20Light%20Gray.png)

Why EMI?

Choosing the right outsourcing partner for your precision manufacturing needs can be the difference between success or failure for a given project. The question is how to choose.

The answer is to optimize for the right relationship. Choose a partner that supports your supply chain needs by delivering responsive service, open two-way communications, and on-time delivery.

For more than a half-century and continuing to this day, EMI always seeks to co-create the right relationship by prioritizing our partners' success.

Our Promise:

“More than Parts: Partnership.”

Contact us today to start building the right relationship.

%20Transparent%20Cropped.png?width=218&height=84&name=EMI%20Logo%20PNG%20(360%20x%20144%2072%20DPI)%20Transparent%20Cropped.png)